In 2010, China’s Academy of Sciences (CAS) and Oak Ridge National Laboratory (ORNL) collaborated on thorium reactor research, driven by China’s interest in reviving thorium-based molten salt reactor technology, an area where ORNL had pioneering expertise from its Molten Salt Reactor Experiment (MSRE) in the 1960s.

Jess Gehin, an ORNL nuclear physicist, described it as an information-sharing pact, with meetings planned a couple of times a year. The collaboration focused on sharing research insights, not building a reactor, with ORNL providing technical knowledge on molten salt systems and thorium fuel cycles while the U.S. gained better understanding of molten salt coolants. China’s goal was to use ORNL’s MSRE work to slingshot into the next-generation nuclear tech. The exchange occurred and ORNL’s role is now historical footnote.

By 2013 CAS’ $350 million Thorium budget was run by Jiang Mianheng, a Drexel EE PhD and the President’s son. Work proceeded on schedule and they initiated the years-long testing of a 2-MW thorium reactor (powers 2,000 homes) in 2021.

Making history

The 2-MW reactor began operating at full power a few weeks ago, a significant event

in nuclear energy history.

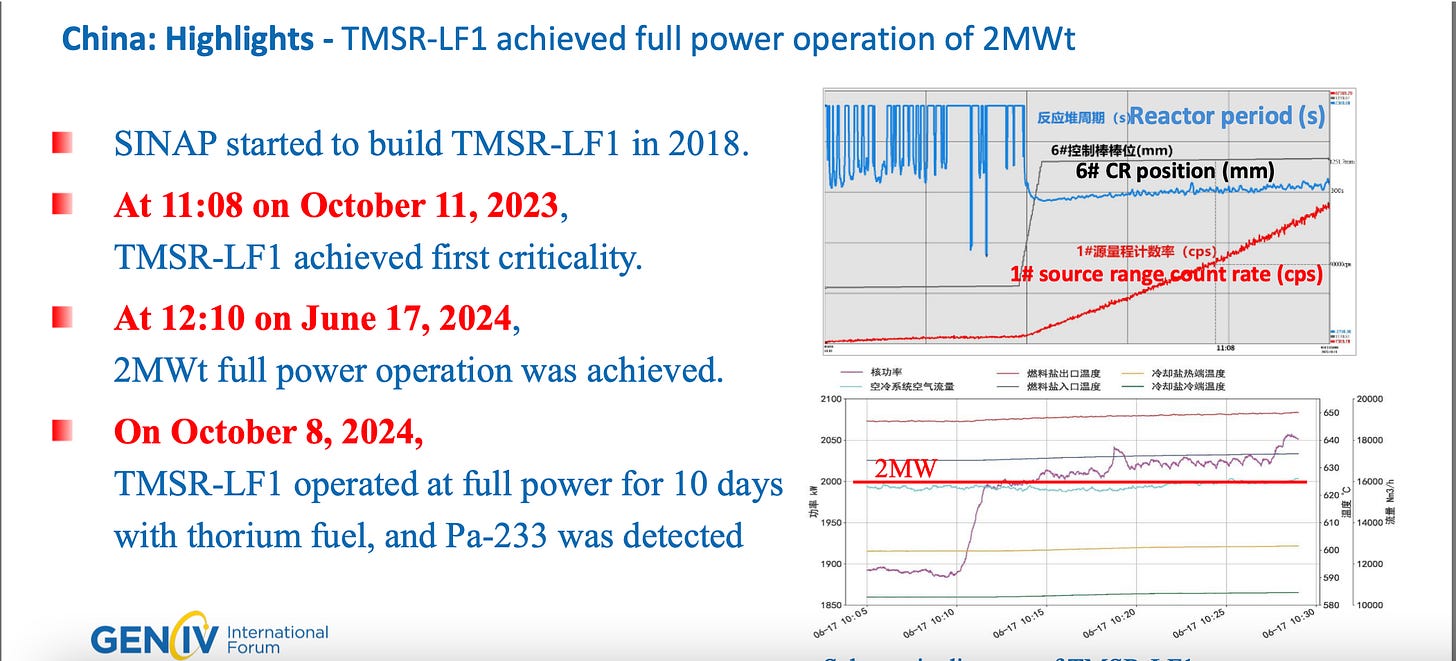

China has built and brought to full power the first thorium-containing molten salt reactor, the TMSR-LF1. Initial criticality occurred on Oct 11, 2023, full power on June 17, 2024. Pa-233, a thorium decay byproduct, was detected Oct 8, 2024. It is the first MSR to run since the US shut down its MSRE in 1969, which ran on enriched U-235 and U-233. Commercial-scale thorium-fueled reactors have run in the past, (Indian Point 1, Shippingport, THTR), but this is the first MSR to do so.

China is on schedule and on budget for the 10-MW reactor in 2030.

Thorium MSREs: A nano-tutorial

The 2MW reactor will discover the disadvantages and inconvenience of a fuel whose conveniences and advantages are numerous:

1. Enhanced Safety

Inherent Stability: MSRs operate with liquid fuel (molten salt) rather than solid fuel rods. If overheating occurs, the liquid fuel expands, naturally slowing the reaction without mechanical intervention.

Fail-Safe Design: A frozen salt plug at the reactor’s base melts during a power loss or emergency, draining the fuel into safe storage tanks, halting the reaction passively.

Lower Pressure: Unlike water-cooled reactors, MSRs run at near-atmospheric pressure, reducing the risk of explosive failures.

2. Abundant Fuel

Availability: Thorium is roughly three to four times more abundant than uranium in the Earth’s crust, with large deposits in countries like India, Australia, and the U.S. It’s often a byproduct of rare-earth mining, making it economically accessible.

Fertile, Not Fissile: Thorium-232 isn’t fissile on its own but converts to fissile uranium-233 when bombarded with abundant, non-radioactive, cheap neutrons, enabling a sustainable fuel cycle.

3. Reduced Nuclear Waste

Less Long-Lived Waste: MSRs produce waste with shorter half-lives compared to uranium reactors. Actinides like plutonium, which linger for tens of thousands of years, are minimized since thorium cycles burn them more efficiently.

Waste Utilization: The liquid fuel allows for online reprocessing, potentially recycling fission products within the reactor, cutting waste volume by up to 90% compared to light-water reactors.

4. Proliferation Resistance

Harder Weaponization: Uranium-233, the byproduct of thorium fission, is contaminated with uranium-232, which emits strong gamma radiation, making it difficult to handle or weaponize without sophisticated shielding—unlike plutonium from uranium reactors.

No Enrichment Needed: Thorium doesn’t require enrichment (a proliferation risk in uranium cycles), simplifying the fuel process.

5. Energy Efficiency

High Burn-Up: MSRs can achieve near-complete fuel utilization, extracting far more energy from thorium than traditional reactors do from uranium, thanks to the liquid fuel’s ability to sustain reactions longer.

Thermal Efficiency: Operating at higher temperatures (600–700°C vs. 300°C in water-cooled reactors), MSRs can pair with advanced turbines, boosting electricity generation efficiency to 45–50%.

6. Versatility

Smaller Footprint: Designs can scale down to modular sizes, ideal for remote areas or developing nations, unlike massive uranium plants.

Heat Applications: The high operating temperatures suit industrial uses like hydrogen production or desalination, beyond just power generation.

7. Environmental Edge

Lower Mining Impact: Thorium’s abundance and simpler fuel prep reduce the environmental footprint of extraction compared to uranium mining and enrichment.

Carbon-Free Power: Like all nuclear, it’s a low-emission energy source, but with potentially less lifecycle waste and risk.

Thorium dreams..

The MSRE that ran from 1965–1969 at Oak Ridge proved these concepts viable—it operated safely, switched fuels mid-experiment (from uranium-233 to uranium-235), and shut down cleanly. China’s successful 2-MW thorium MSR builds on this, aiming for a commercial edge by 2030. Thorium reactors could outpace uranium reactors in safety, modularity and sustainability, though challenges like corrosion and regulatory hurdles remain.