The truth is, China stopped being the low-labor-cost country many years ago. The reason to come to China is the skill, and the quantity of skill in one location and the type of skill...Our products require really advanced tooling, and the precision that you have to have, the tooling and working with the materials that we do are state of the art. And the tooling skill is very deep here. In the US, you could have a meeting of tooling engineers and I'm not sure we could fill this room. In China, you could fill multiple football fields... - Tim Cook, Apple CEO

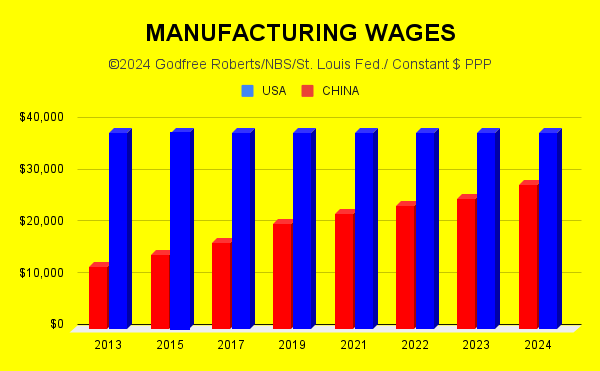

A friend, a director-level employee with an engineering background, who has worked with multinational companies in various capacities while primarily based in the US, wrote me, "American manufacturing moved to China not because of dumb labor, but because you could hire high IQ people for dirt cheap. If your machine broke down, no problem; some Chinese guy (with basically a masters in EE) would pull out the circuit boards and using probes and other instrumentation determine what board needed replacing and he would work annually for a fraction of the salary of his equivalent in the US.

Manufacturing in the US

Manufacturing here is a nightmare: at our US facility our only requirement for a assembler was a high school degree, US citizenship, passing a drug and criminal background check and then passing a simple assembly test: looking at an assembly engineering drawing and then putting the components together. The vast majority of Americans were unable to complete the assembly test, while for our facility in China they completed it in half the time and 100% of the applicants passed. An assembler position in the US would average maybe 30 interviews a day and get 29 rejections, not to mention all the HR hassles of assemblers walking off shift, excessive lateness, stealing from work, slow work speed and poor attitudes.

The product line is highly specialized equipment, so it makes no sense to fully automate it, most of the components are assembled by hand and for certain steps we use custom engineered jigs. And for those saying that the position wasn't paying enough, it paid $12 an hour starting in an area with an extremely low cost of living where property taxes for a 2000 square foot house would be $800-$1000 a year. Assemblers don’t make $150K. An assembler puts parts together. The position starts at $12 an hour in flyover country which is pretty reasonable compared to other jobs that only require a GED and no prior work experience. Offers medical, dental and annual raises with plenty of opportunity to move up in the company. The national average salary for a Production Assembler is $33,029 in United States, which is what you would be making if you stayed for 5+ years.

Finding an American worker capable of passing these simple requirements and passing the assembly test is merely impossible. Never mind being competent, punctual and of good moral character (not stealing from company or starting conflicts with coworkers). And these are the main groups that apply for this position.

Labor in China

The same exact product line has the same facility in China, and the same positions in China pays the same wages as other positions there with only a high school degree and no work experience.

Yet the applicant quality is much higher, and this applies as well to the white collar professions that support the manufacturing: schedulers, quality inspectors, equipment testers and calibrators, engineers, supply chain managers, account managers, sales etc....their labor quality is simply higher.

P.S. I suspect our blacks and Hispanics are too dumb to get affirmative action to go to college, so they probably average 75 IQ. Their Chinese equivalents are probably 95 but the performance gap is massive.

Good piece, but I could have done without the racist rant at the end. Two of the most highly performing ethnic groups in the US are Nigerians and Afro-Caribbeans.